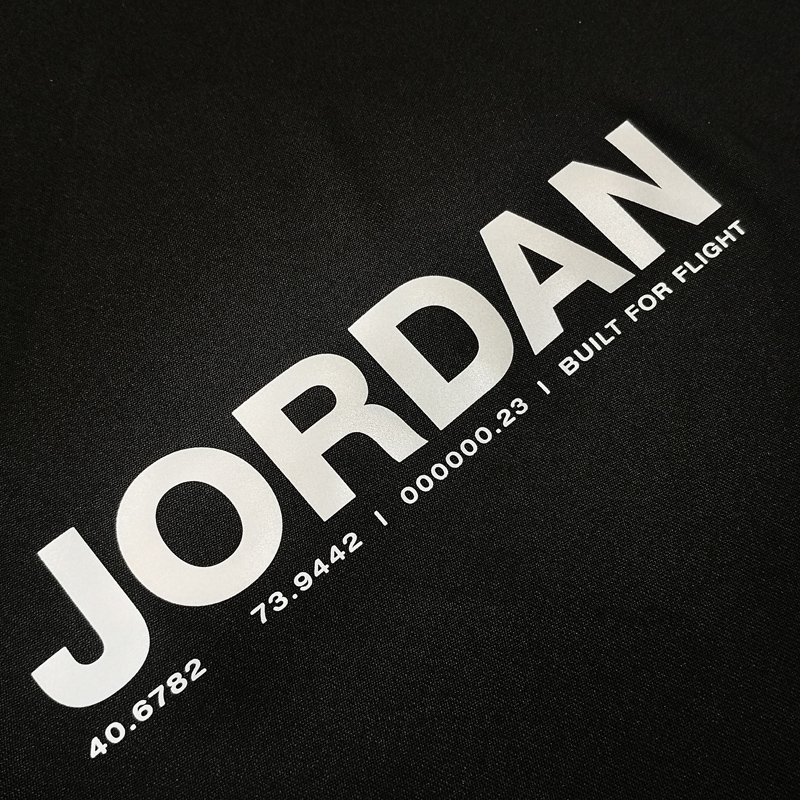

Spots Color Reflective Labels

1. Retroreflection coefficient: up to EN20471 secondary standard

2. Washing resistance: can reach ISO6330 stipulated by EN471; 2A washing more than 25 times.

3. Dry cleaning resistance: according to ISO3175 standard, it can be dry cleaned more than 5 times

4. Environmental protection requirements: This product does not contain toluene, azo, free heavy metals, etc. in line with Oeko-Tex Standard 100, REACH regulations and other EU environmental protection standards.

Our company is a professional manufacturer of reflective materials. Its reflective series products are reflective glass beads with high refractive index, which are densely coated on various resin substrates to produce a strong reflective effect, which is widely used in various fields. , With many traffic safety and personal outdoor sports products, such as traffic signs, clothes, sports shoes, hats, bags, umbrellas, raincoats, tents and other outdoor products.

We can produce color and silver reflective cloth, reflective PU, reflective TPU, reflective melt-off film, reflective PVC, reflective webbing, reflective trademarks, reflective silk, reflective edge wrapping strips, etc. In addition to the above products, our company can also specially design for customers And manufacture other types of reflective products to meet the needs of different customers.

Our products have passed the EU REACH standard and environmental protection standard, and have valid test reports.

1. Placement: When using, peel off a layer of plastic protective film or white release paper on the back of the thermal film, and place the back of the reflective transfer image (the rough surface is the back - the smooth surface is the front) on the back of the substrate. in the position where it should be;

2. Warming: Attach a thin cotton cloth to the heating place of the heat press machine, and then warm it on the cotton cloth.

3. Transfer printing: The pressure of the heat press machine is 4 kg. Please ensure that the level of the table and the temperature of the heat transfer board are consistent with the display temperature. At the same time, it is necessary to check whether the temperature of the heat transfer board is uniform. The transfer temperature and time depend on the melting point of the hot melt adhesive and the fabric, usually 150°C for 15 seconds.

4. Tear film: After the transfer is completed, the reflective film needs to be cold-teared from the PET film. Press the cloth with your hand and tear the film parallel to 180 degrees.

5. Our reflective film has made a lot of efforts on the problem of sticking to the cloth. Common types of cloth (20 kinds of cloth have been tested) will not appear sticking and indentation after ironing.

Each product has undergone a number of testing technologies, and all products will undergo three quality inspections by procurement, QC, and warehouse management personnel before shipment to ensure that the products delivered to you are qualified products. Confirm as soon as possible after receiving the product. Any quality problems can be returned.

According to your requirements and quantity, we will give you the exact time as soon as possible; generally 3-5 days.