Custom Super Elastic Eco-friendly Ink for heat transfer

1, safety first. When storing ink, keep away from fire and heat sources as much as possible to prevent accidents.

2, it is best to maintain a constant temperature in the ink warehouse, and the temperature difference with the printing workshop should not be too different. If the temperature difference between the two is large, the ink should be placed in the printing workshop in advance, which is not only conducive to the stability of the ink performance, but also ensures high production efficiency.

3, in some northern areas, the climate is relatively cold in winter, so avoid storing the ink outdoors to prevent the ink from gelling at low temperatures. If the ink gels, it can be transferred to a warehouse with a higher temperature, or placed in hot water to restore the insoluble matter to its original state.

4, in the storage and management of ink, the principle of "first-in, first-out" should also be followed, that is, the ink purchased first is used first, so as to prevent the ink from being affected by the long storage time.

5, the ink should not be stored for a long time. Generally, the storage period is about 1 year. Otherwise, it may affect the printing quality and even cause printing failure.

6, the remaining ink after printing must be sealed and stored in a dark place, which can be reused in future production.

7, it is best to seal it to avoid dust.

1. Take out the required ink. Before printing, please do a trial printing to test the matching of the ink to the printing material.

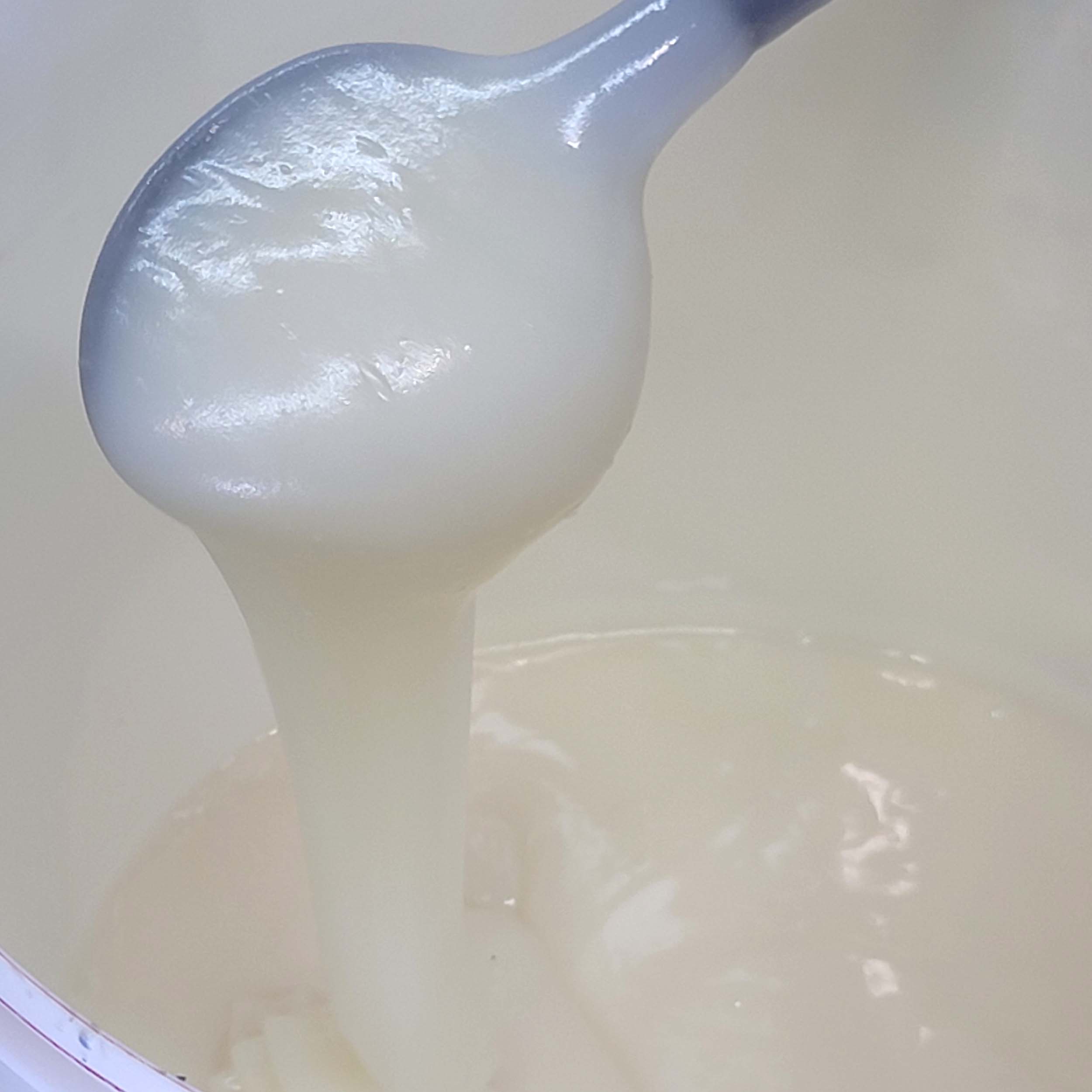

2. If the ink concentration is too high, add an appropriate amount of thinner

3. Before printing, remove the dust and oil stains on the surface of the substrate, which can be removed with absolute ethanol (alcohol) or wiping water.

Fourth, after the ink is completely stirred, it can be poured onto the screen or steel plate (not directly into the printing area) for printing.

Fifth, in the case of pure manual operation, after the scraper scrapes the pattern, it is necessary to gently push the glue back to cover the printing ink leakage area, wet the mesh, and prevent the mesh from being blocked.

Sixth, after printing the current product, the rough inspection should be carried out immediately, and the next product should be printed immediately to avoid the situation of poor quality printing on a large scale, and also to avoid the situation of ink blocking the screen due to too long intermediate residence time.

Seven, the drying time of the ink layer after printing will vary depending on the substrate to be printed. To ensure the quality after printing, it takes 15 minutes for natural volatilization drying and surface drying to dry for more than 24 hours (due to different climates and printing environments), It can also be dried at a temperature higher than 60°C.